What is the die casting process used for?

Die casting is a manufacturing process used to create metal parts by forcing molten metal into a mold cavity under high pressure. This process is commonly employed for producing complex shapes with high precision and smooth surfaces. Here are some key uses and advantages of die casting:

1. Automotive Components:

Die casting is widely used in the automotive industry for parts like engine blocks, transmission cases, and other components that require durability and strength.

2. Consumer Electronics:

Many electronic devices, such as housings for smartphones, laptops, and other gadgets, utilize die cast metal parts for their lightweight and resistant properties.

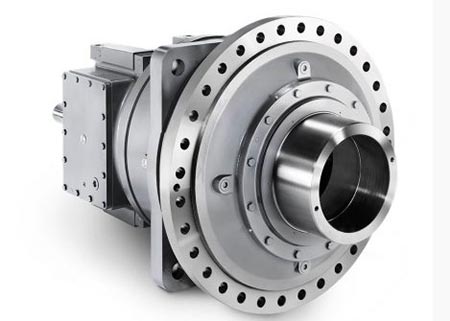

3. Industrial Machinery:

Parts for various machinery, including housings and structural components, can be efficiently produced using die casting.

4. Aerospace:

Die casting can be used to manufacture lightweight, strong components for aerospace applications, contributing to overall efficiency.

5. Home Appliances:

Components like frames, housings, and brackets in appliances are often made through die casting due to the process’s efficiency and cost-effectiveness.

Advantages of Die Casting:

– High Precision: Produces parts with tight tolerances and complex geometries.

– Smooth Surfaces: Minimizes the need for secondary machining operations.

– High Production Rates: Suitable for large volumes of production, which reduces per-unit costs.

– Material Efficiency: Generates less waste material compared to some other manufacturing processes.

Overall, die casting is an essential process in industries where metal components are required, providing both quality and efficiency in manufacturing.