What is die casting mold?

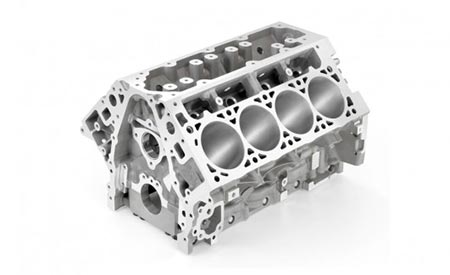

Die casting molds, also known as die molds or dies, are specialized tools used in the process of die casting. Die casting is a manufacturing process used to produce metal parts with high dimensional accuracy and smooth surface finishes.

The die casting mold is typically made of two hardened steel halves, referred to as the die halves or die inserts. These halves are precisely machined to create cavities that correspond to the shape of the desired part. When the two halves are brought together, they form a complete mold cavity.

During the die casting process, molten metal is injected into the mold cavity under high pressure. The metal solidifies quickly within the cavity, taking on its shape. Once solidified, the mold opens, and the part is ejected.

Die casting molds are designed to withstand the high pressures and temperatures associated with the process. They are often engineered with features such as cooling channels to control the temperature of the mold and ensure proper solidification of the metal.

Die casting molds are crucial to the efficiency and quality of the die casting process. Proper design and maintenance of the molds are essential for producing high-quality parts consistently.

What is the lifespan of die cast mold?

The lifespan of a die cast mold can vary significantly depending on several factors such as the type of material being cast, the complexity of the mold design, the quality of the mold construction, and the maintenance practices. Generally, the lifespan can range from tens of thousands to hundreds of thousands of cycles. Here are some key factors that influence the lifespan of a die cast mold:

1. Material of the Mold: High-quality steel molds typically have longer lifespans than those made from softer materials.

2. Type of Casting Material: Different metals have different impacts on mold wear. For example, aluminum casting tends to be less abrasive than magnesium or zinc casting.

3. Design Complexity: Molds with intricate designs may wear out faster due to more complex thermal and mechanical stresses.

4. Operating Conditions: Higher casting temperatures and pressures can reduce mold life. Consistent and optimized operating conditions help extend mold life.

5. Maintenance and Repairs: Regular maintenance, including proper cleaning, lubrication, and timely repairs, can significantly prolong the lifespan of a mold.

6. Production Volume: Higher production volumes can accelerate mold wear, reducing its effective lifespan.

7. Coatings and Surface Treatments: Protective coatings and surface treatments can enhance mold durability and resistance to wear and corrosion.

Typically, a well-maintained high-quality die cast mold can last anywhere from 100,000 to 300,000 cycles. In some cases, with optimal conditions and maintenance, molds can exceed this range, reaching up to 500,000 cycles or more. However, each application and operating environment can affect these estimates.

How to make a die cast mold?

Die casting is a manufacturing process that involves pouring molten metal into a mold to create intricate shapes. Creating a die-cast mold is a crucial part of this process, as it directly impacts the quality of the final product. Here’s a step-by-step guide on how to make a die-cast mold:

1. Understand the Basics of Die Casting

Die Casting Materials: The most commonly used materials for die casting are aluminum, zinc, and magnesium. These metals are chosen for their ability to be cast into complex shapes with high precision.

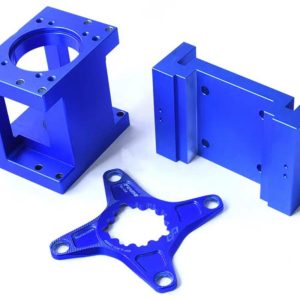

Types of Molds: There are two main types of die casting molds:

Single cavity mold (for one part at a time).

Multi-cavity mold (for producing several parts simultaneously).

2. Design the Die Cast Mold

3D Modeling: Use CAD software to design the mold. The design should consider the final product’s dimensions, the metal’s shrinkage during cooling, and the ease of removing the casting from the mold.

Gate and Vent Placement: Design the gates and vents to ensure proper metal flow and gas escape during casting.

3. Select the Die Cast Mold Material

Tool Steel: Most die-cast molds are made from tool steel due to its durability and resistance to the high temperatures of molten metal.

Considerations: Choose a mold material that can withstand the thermal stresses of repeated casting cycles.

4. Machining the Die Cast Mold

CNC Machining: Once the mold design is finalized, CNC machining is used to create the mold. This involves cutting, drilling, and shaping the mold according to the design specifications.

Electrode Production: If the mold has complex features, Electrical Discharge Machining (EDM) might be used. EDM uses a shaped electrode to burn the mold’s cavity shape.

5. Heat Treatment

Hardening: After machining, the mold undergoes heat treatment to increase its hardness and durability.

Stress Relief: This step ensures that the mold does not warp or deform during the casting process.

6. Polishing and Finishing

Polishing: The interior surfaces of the mold are polished to ensure a smooth finish on the final cast product.

Surface Coating: Sometimes, a surface coating is applied to reduce wear and extend the mold’s life.

7. Testing the Die Cast Mold

Trial Casting: Conduct a trial casting to check for defects in the mold design or machining. This test ensures that the mold produces parts with the desired quality and accuracy.

Adjustments: If any defects are found, adjust the mold accordingly and retest.

8. Finalizing the Die Cast Mold

Assembly: If the mold is a multi-part design, assemble all components and ensure they fit together perfectly.

Maintenance: Implement a maintenance plan to keep the mold in good condition, including regular cleaning and inspection for wear.

9. Mass Production

Once the mold is ready and tested, it can be used in a die-casting machine to produce parts in large quantities. The mold will need regular maintenance to ensure consistent quality over time.