About Bian New Energy Vehicle Project by CNC Machining

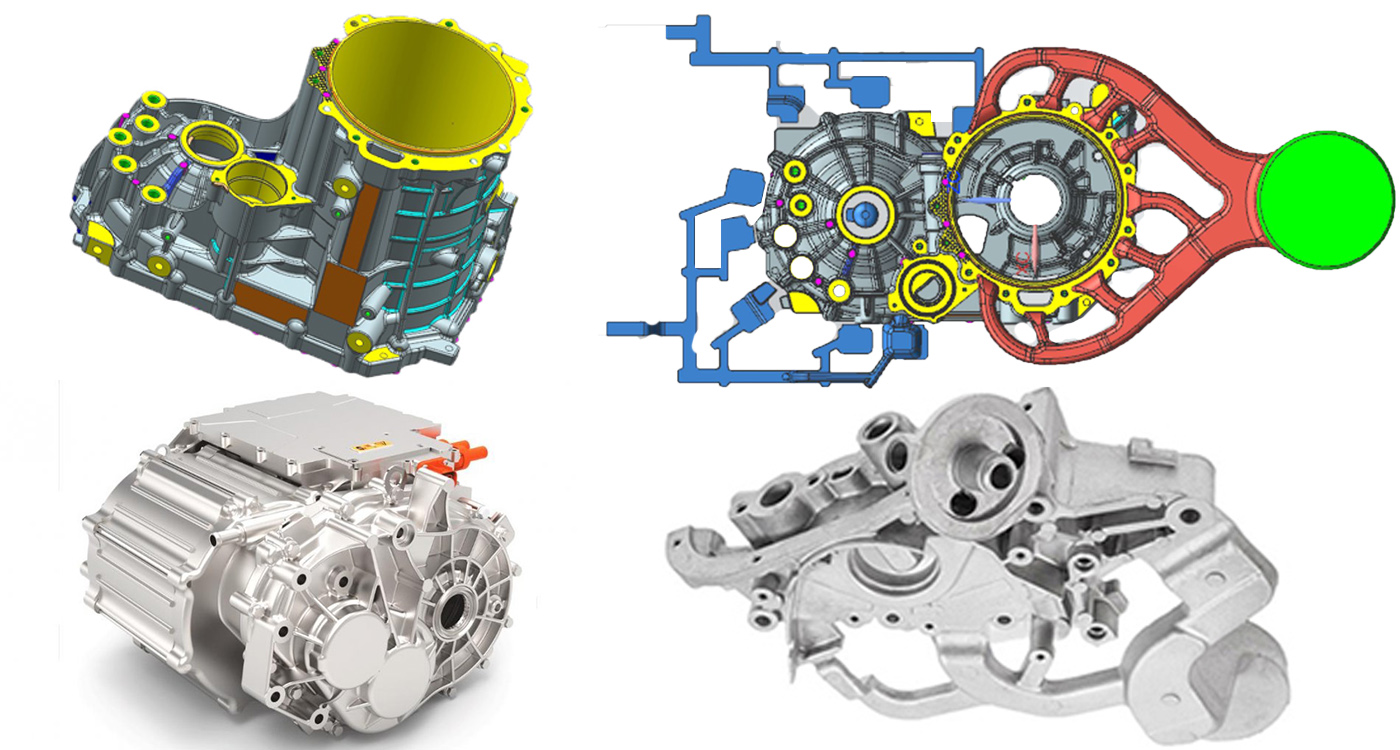

As we knew that there are more and more deterioration for our environment, green and low carbon has become the main theme topic of global development. The new energy vehicles have quickly developed as large quantity request in the marketing. BIAN, as a global leader on prototyping and its die casting parts production, has a huge capacity to help the new energy vehicles projects with its important Vehicle three-electricity system parts production by aluminum die cast and CNC machining.

1.How can BIAN help with New Energy Vehicle projects in design and prototyping stage?

In R&D product development, having design capabilities is not enough. It is critical to also have the capacity to turn a design into a product using the right materials and processes from the very beginning. How to verify and test it? The answer is you need a professional prototyping manufacturer.

When we got the model 2d/ 3d data from the clients for quoting, our engineer team will review and analyze the design if it’s suitable for manufacturing and how to achieve functional purpose with lower cost, then perfect improvement suggestion will come to you as soon as possible.at the meanwhile, we’ll suggest to add small radius rather than EDM machining. Which greatly help to save cost & time, and ensure the parts can be used as functional. After testing with prototyping by CNC machining, It turns out our solution it’s working very well and save time and cost, which lead to the aluminum casting parts production stage smoothly.

2.How can BIAN help with New Energy Vehicle projects in aluminum casting parts production stage?

BIAN not only helps our client make their concept/design come true by prototyping, but also offers small volume production parts as per their market demands. After several rounds prototyping and verify on functional and assemble, the needs of parts it’s increasing, with previous communication and understanding of project, we can save a lot of time on communication. We have a PPAP control plan and huge capacity to support aluminum casting parts production orders with tight lead-time. With 100 sets CNC machines, we even finish larger Auto parts and deliver smoothly to our customer per week.

3.How can BIAN help to ensure quality of New Energy Vehicle projects?

We have professional and dedicated QC team. We create a completely control plan, and have a good training for all participating staff. During production ,we guarantees the on-line and off-line inspection to ensure the parts produced correctly and goods quality is under control. All details of parts will check with suitable test devices and instruments like2.5D detector,CMM, metal spectrometer, spectrophotometer,salt spray tester,X-ray detector, abrasion tester,air tightness tester,color measurement,environmental Tester etc..

We always follow the standard tolerance ISO-9001 and IATF 16949 certification standard.