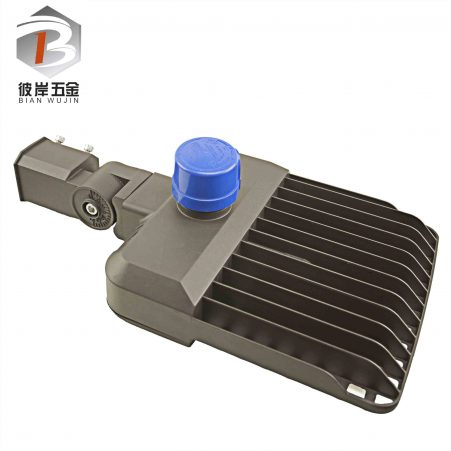

die casting Aluminum alloy Services moulds for housing cases of outside street LED lights

Mold Material | SKD61, H13 |

Mold Life Time | 50K times |

Product Material | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

Surface Treatment | Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodize |

Size

| 1) According to customers’ drawings 2) According to customers’ samples |

Drawing Format | step, dwg, igs, pdf |

Lead Time: | Depends On Order Quantity.Normally 10~30 Days |

Heat Treatment: | Anneal,Quenching,Normalizing,Carburizing,Polishing,Plating, Painting,etc |

Machining Equipment: | CNC Machines, Laser Machines,Cast Machine,Turning Machines , Milling Machines, Grinding Machines,Painting Machines,EDM Machines,Testing Machines. |

Application: | Auto Parts, Furnishing Parts, Construction/Architecture/Machinery Parts, Street light case,Medical Parts,Electrics Parts etc. |

street light 100w precise die casting moulds for outside use

- The shell adopts the high quality of lams and lanterns aviation aliumium die-casting, surface after polishing, nano electrostatic spraying, introduced large lamp plate heat dissipation design, greatly improve the feeect of light and heat dissipation problems, effectively ensure the service life of light source and power supply in the bad environment.

- The lamp body adopts toughened glas and silica gel seal to meet the IP67 standard, and the excellent waterproof, dustproof and anti-corrosion design can be used in rainy or cold areas ofor al long time.