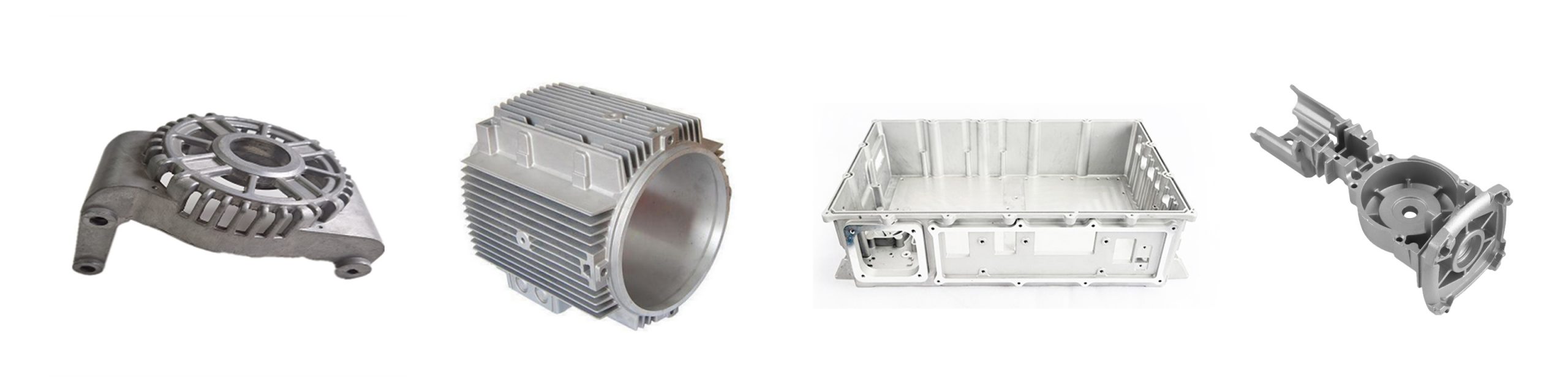

New energy auto parts

CNC Machining Parts for New energy auto parts Battery housing

|

Product Name |

New Energy Alloy Die Cast Parts Factory |

|

Material |

Aluminum alloy: ADC12, A360, A380 etc. |

|

Zinc alloy: zamak 3, zamak 5 etc. |

|

|

ToleranceTolerance |

+/-0.05mm~+/-0.2mm |

|

Service |

OEM service, R&D team supported |

|

Drawing format |

PDF, DXF, DWG, STEP, stp, X-T etc. |

|

Surface Treatment |

Polishing, anodizing, powder coating, passivating, painting, plating, sand blasting, e-coating and others |

|

Process |

Design confirm-Tooling design- Tooling testing-Die casting- Degating- Polishing- CNC machining- Deburring- Inspecting- Surface treatment- Inspecting- Packing |

|

Main Production Equipment |

Cold chamber die casting machine, hot chamber die casting machine, CNC machine, drilling machine, tapping machine, multi-axis tapping machine, sand blasting machine etc. |

|

Main Testing Equipment |

X-ray / 2.5 measuring instrument / CMM / height gauge / metal spectrometer / Roughness measurement / Salt Spray testing machine /Colorimeter etc. |

|

Certificate |

ISO9001:2015, IATF16949 |

|

Application |

New energy auto parts |

|

New energy Motocyle |

The shell adopts the high quality of different type of new energy car ‘s battery, surface after polishing, nano electrostatic spraying, inspected by 15 types of advanced instruments like X-ray,CMM,IP tester, Salt spray…etc.. greatly prevent safety problems, effectively ensure the car parts works a very long time.

We have 10 brand die casting machines, 20 CNC machines, 10 polishing machines, 5 milling machines and other type of machines,with an annual output of more than 500 sets of die-casting molds.Our team will help you to make product from concept to production.Our die casting machines range from 180T up to 1250T, we can produce die casting parts from a few grams to more than 100 pounds with superior quality ready for assembly