The Application of Lightweight Aluminum Die Casting Technology in the Automotive Industry

As the automotive industry rapidly develops, lightweighting has become a key factor in improving vehicle performance and reducing energy consumption. Lightweighting not only enhances vehicle dynamics and fuel economy but also reduces emissions and energy consumption.

What is Lightweight Aluminum Die Casting Technology?

Lightweight aluminum die casting technology is a manufacturing method aimed at producing lightweight, high-strength, and complex-shaped aluminum alloy parts. This technology involves injecting liquid aluminum alloy into metal molds, followed by rapid solidification and curing under high pressure to form the desired shape of the parts. Compared to traditional casting processes, aluminum die casting technology can achieve higher production efficiency, more precise dimensional control, and better surface quality. This technology is widely used in industries such as automotive manufacturing to meet the demand for lightweight, high-strength, and complex-shaped parts. Key technologies include:

1.Precision Cutting Technology

Precision cutting technology is a crucial step in aluminum die casting processing. High-precision cutting equipment can achieve precise dimensions and smooth surfaces, thereby improving the quality and performance of aluminum die-cast parts. Laser cutting and plasma cutting are common precision cutting technologies known for their fast cutting speed, good cut quality, and high processing accuracy.

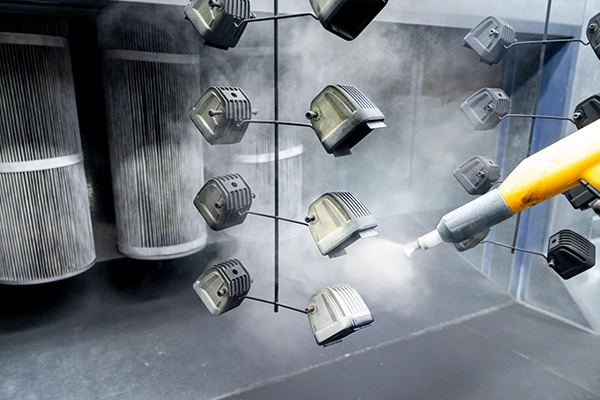

2.Surface Treatment Technology

Aluminum die-cast parts are prone to oxidation on the surface, affecting their corrosion resistance and appearance. Therefore, surface treatment technology is essential in aluminum die casting processing. Common surface treatment technologies include anodizing, plating, coating, etc. These technologies can improve the corrosion resistance, wear resistance, and appearance quality of aluminum die-cast parts.

3.Precision Mold Design

Precision mold design is one of the core technologies in aluminum die casting processing. With reasonable mold design and manufacturing, precise dimensions and good surface quality can be achieved. At the same time, precision molds can improve production efficiency and reduce production costs.

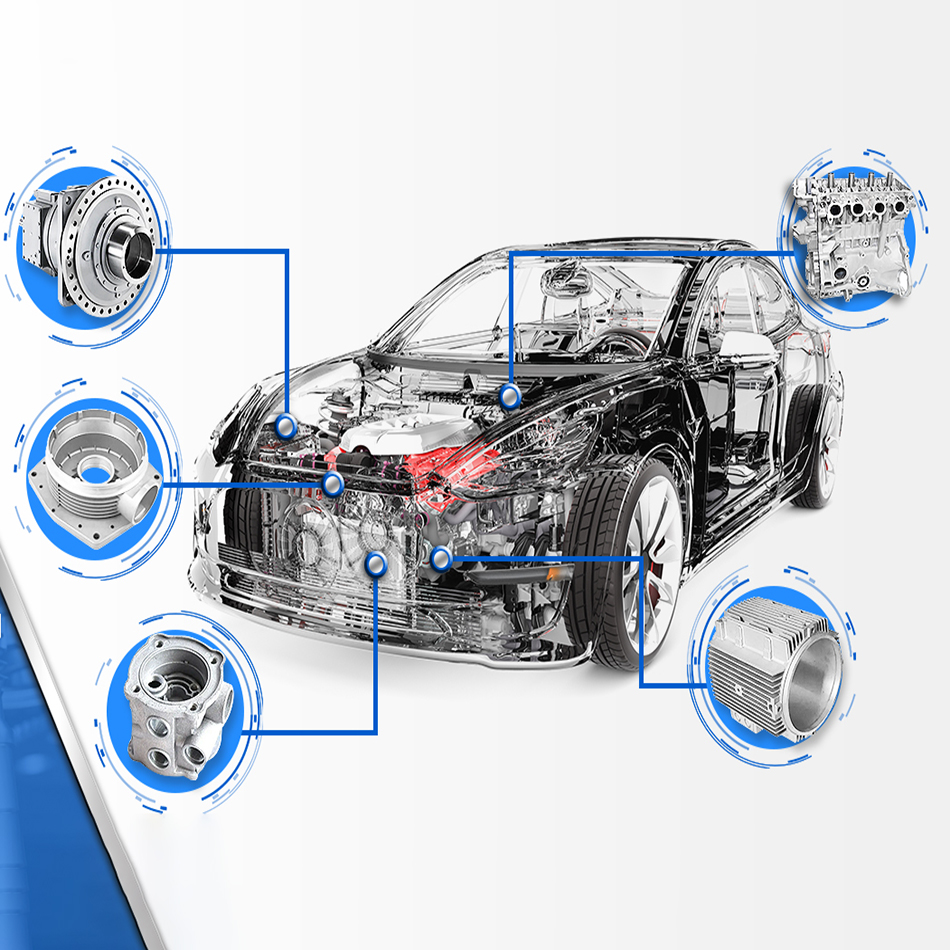

The Application of Lightweight Aluminum Die Casting Parts in the Automotive Industry

1.Engine Components

The engine is the heart of the car, and lightweighting is essential for improving vehicle performance and reducing energy consumption. Aluminum die-cast parts are widely used in engine components such as cylinder heads, cylinder blocks, exhaust pipes, etc. The application of lightweight aluminum die-cast parts can reduce the weight of the engine, improve power performance, and fuel economy.

2.Body Components

Lightweighting of body components can reduce the overall weight of the vehicle, improve power performance, and fuel economy. Aluminum die-cast parts are widely used in body components such as body frames, suspension systems, wheels, etc. The application of lightweight aluminum die-cast parts can reduce the overall weight of the vehicle, improve driving stability, and safety.

Lightweight aluminum die casting technology plays a significant role in the automotive industry. Through key technologies such as precision cutting, surface treatment, and precision mold design, precise dimensions, good surface quality, and higher quality performance can be achieved. The application of aluminum die-cast parts in engine components and body components can reduce the overall weight of vehicles, improve power performance, and fuel economy. In the future, with the continuous development of lightweighting technology, the application of aluminum die-cast parts in the automotive industry will become more extensive.